Liquid crystal injection and sealing process

After preparing the empty liquid crystal box and liquid crystal material, it is time to inject the liquid crystal material into the empty box. In order to improve the reliability of the liquid crystal display device, the empty box and the liquid crystal material must be thoroughly degassed before injecting the liquid crystal material into the empty box. After the liquid crystal is injected, it must be tightly sealed to prevent the intrusion of impurities or gas from affecting the quality of the display device.

1. Liquid crystal injection

1) The process principle of liquid crystal injection

The empty box is placed in a vacuumed liquid crystal filling closed chamber, the gas in the box is extracted from the seal, and then the seal is brought into contact with the liquid crystal and the vacuum chamber is inflated. The liquid crystal is filled into the empty box under the action of external air pressure.

(1) Vacuum degassing treatment:

Generally, the inner surface of the empty box made in the atmosphere is adsorbed with water and gas that are harmful to the liquid crystal material, and other gases may also exist. These water, air and other gases can be electrolyzed when the liquid crystal display device is working, generating gases and other impurities that are harmful to the liquid crystal. If a small amount of bubbles are generated, since the volume of the liquid crystal box is very small, the performance of the display part will be reduced due to the instantaneous expansion of the bubbles. In addition, when an electrode reaction occurs due to the influence of bubbles or impurities, the transparent electrode will turn black, forming a latent image that cannot disappear. Therefore, in order to effectively prevent these drawbacks, the empty box and liquid crystal material must be evacuated and exhausted.

(2) Injection of liquid crystal:

Generally, when the empty box is not large, under certain vacuum conditions, most of the volume of the empty box can be injected into the liquid crystal material by using only the capillary phenomenon. Therefore, after the empty box and the liquid crystal material are evacuated, the bonding gasket can be pressed into the injection hole (the gap of the sealing frame) of the liquid crystal box, and the liquid crystal material can be slowly injected into the empty box from its storage container through the bonding gasket. After most of the empty box is injected with liquid crystal material, the liquid crystal perfusion chamber is filled with fully dried argon or nitrogen and other inert gases, and the pressure of the inert gas is used to fill the liquid crystal box with liquid crystal material.

2) There are two basic methods of infusing liquid crystal, namely needle infusion and immersion infusion.

Needle-type infusion is to evacuate the empty box, dip the needle in liquid crystal and place it on the seal, so that the liquid crystal completely covers the seal, and then fill the liquid crystal into the box through air pressure. When using needle-type infusion, the amount of liquid crystal is saved. This method is only suitable for products with small seals, and bubbles are easily generated during infusion.

Immersion infusion is to invert the empty box that has been evacuated into a vacuum on a sponge filled with liquid crystal, and use the external air pressure after inflating to fill the liquid crystal into the box. With immersion infusion, more liquid crystal is used, which is suitable for seals of any size, and fewer bubbles are generated during infusion.

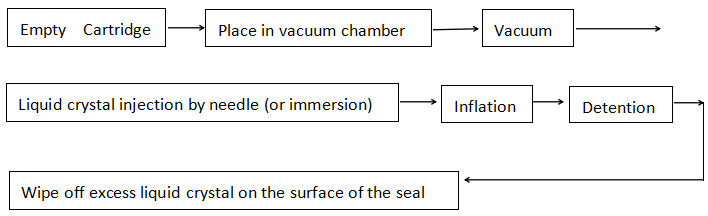

3) Process flow of liquid crystal injection

The process flow of liquid crystal injection is shown in the figure.

2. Liquid crystal box sealing

1) Introduction to Liquid Crystal Cell Sealing

The sealant is used to bond the seal, and the sealing glue is allowed to shrink appropriately and enter the seal through freezing. Then, through the action of light or heat, it undergoes chemical crosslinking or polymerization to form a firm seal. The sealing process can be achieved in two ways. One method is to allow the liquid crystal in the liquid crystal box to expand due to heat and discharge a small amount of liquid crystal from the box, and then apply the sealing glue to allow the glue to shrink a small amount and then solidify the glue. This method requires more complex equipment, but the uniformity of the box is good. Another method is to seal the seal with sealing glue first, and then freeze the liquid crystal to shrink and bring in a small amount of sealing glue, and solidify it. This method is simple to operate and low in cost, but the uniformity of the box is poor.

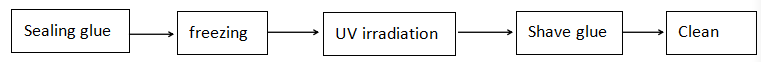

There are two methods for dispensing glue: manual dispensing and automatic dispensing. There are two methods for curing the sealing glue: UV curing and thermal curing. UV curing uses UV irradiation to cure the sealing glue; thermal curing uses heating to cure the sealing glue. At present, most LCD manufacturers use UV irradiation curing.

2) Liquid crystal box sealing process

The process flow of UV curing sealing of liquid crystal box is shown in the figure.

3. Precautions for LCD and sealing operation

The precautions for liquid crystal and sealing operations are as follows:

1. When pouring, first align the pouring port with the sponge strip that absorbs the liquid crystal. When aligning, the pouring port must not be stained with liquid crystal

2. The pouring time should be determined according to the structure and size of the liquid crystal box. If the time is too short, the pouring will not be full

3. During the pouring, no impure substances must enter the liquid crystal box, otherwise the display quality of the box will be significantly reduced, or even scrapped

4. Wipe the sealing area before sealing, otherwise it will affect the bonding quality of the sealing glue.

5. The sealing glue must have a certain amount of glue. Too little will reduce the sealing performance, and too much will affect the appearance and use requirements

6. After sealing, be sure to remove the remaining sealing glue, liquid crystal and other dirt on the surface of the LCD screen to ensure the quality of post-processing.

Rearrange

After the liquid crystal is poured into the liquid crystal box, the alignment of the liquid crystal usually does not meet the requirements and needs to be re-aligned. The method is to put the liquid crystal box into a heating box and keep it at a certain temperature for a period of time. By heating, the liquid crystal molecules interact with each other and adjust the alignment state of the liquid crystal molecule director, and finally achieve a regular arrangement of the liquid crystal in the liquid crystal box.

For more information about liquid crystal filling and sealing process, please contact us directly!

Search

Search